Why our automated dynamic wood drying process outperforms the competition.

Understand the science behind our innovation in wood drying.

Understand the science behind our innovation in wood drying.

Before the Alent Dynamic® method - dynamic wood-drying process with interval drying as the method - the way in which we dry timber had not changed in any significant way for over half a century. The conventional methods both waste a lot of energy.

We found a process much closer to how nature actually works, only faster; a method that puts significantly less stress on the timber, but is still faster than the conventional methods, and requires a lot less energy.

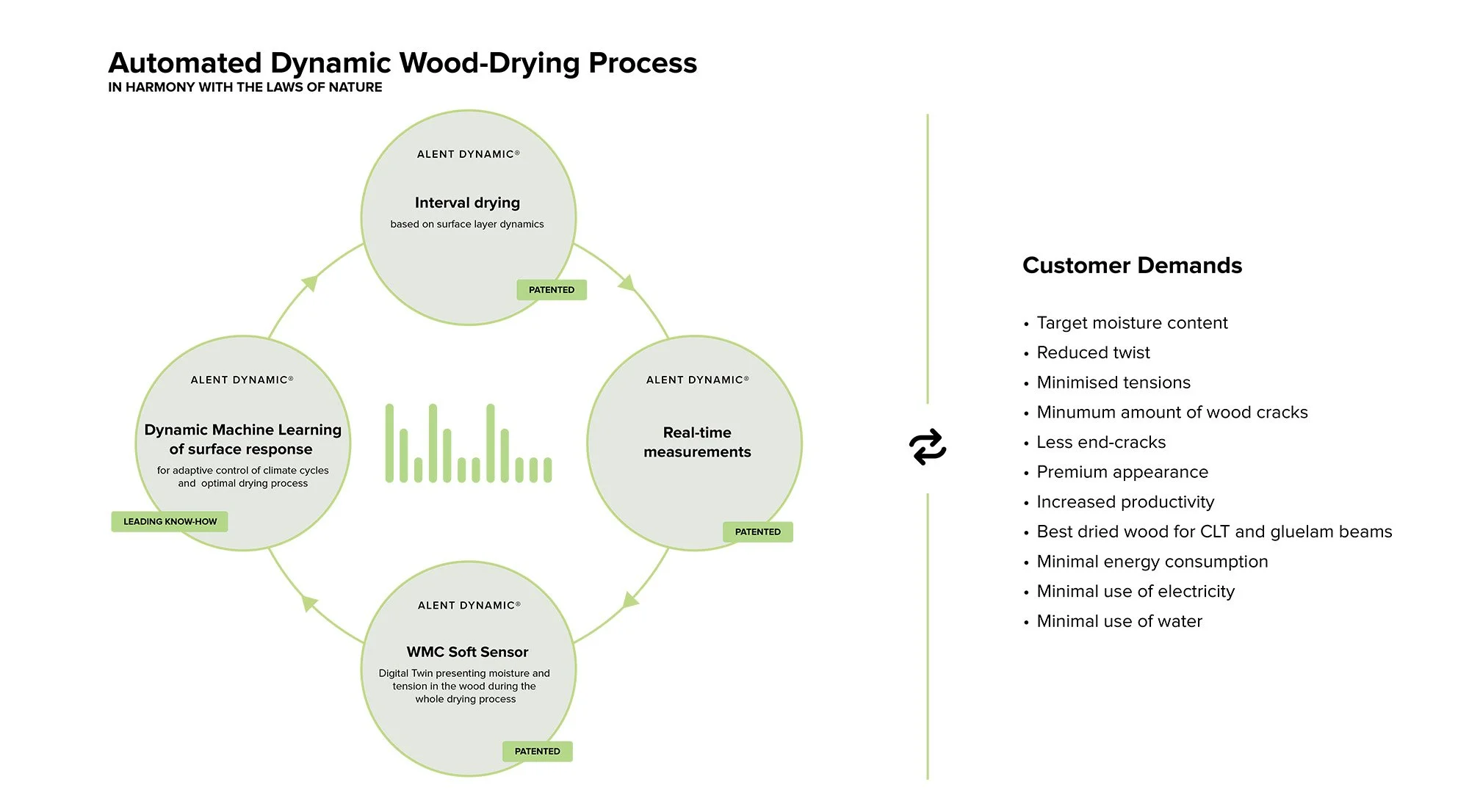

Today this dynamic wood drying process, based on our patented method, is automated to meet defined customer requirement.

Conventional wood drying

since 1950

The wood is bombarded with an uninterrupted flow of hot air from start to finish.

The "slow-down" method

since 1990

The fans are set to gradually slow down near the end of the drying process, but the flow of hot air remains constant.

Our PATENDED Dynamic wood-drying process, with Interval drying as the method

since 2010

The patented Interval drying from Alent Dynamic alternates between short intervals where fans and ventilation run at full power, and longer intervals of rest. The dynamic wood-drying process consists of four components; interval drying (patented), real-time measurement (patented), WMC (patented) and adaptive control for each drying cycle.

When wood is bombarded with hot air, the surface (“the shell”) becomes both hotter and dryer than the core. The relative difference in moisture content — the moisture gradient — is what drives the migration (“diffusion") of moisture.

Unfortunately, the difference in temperature — the temperature gradient — does the exact opposite.

In conventional drying, the temperature on the surface of the wood is always higher than at the core (because the hot air bombardment never stops). This means that the temperature driving force always counteracts the migration of moisture.

On top of that, the constant difference in temperature and moisture content causes both tensile and compressive stress in the wood, which invariably leads to a degradation of end product quality.

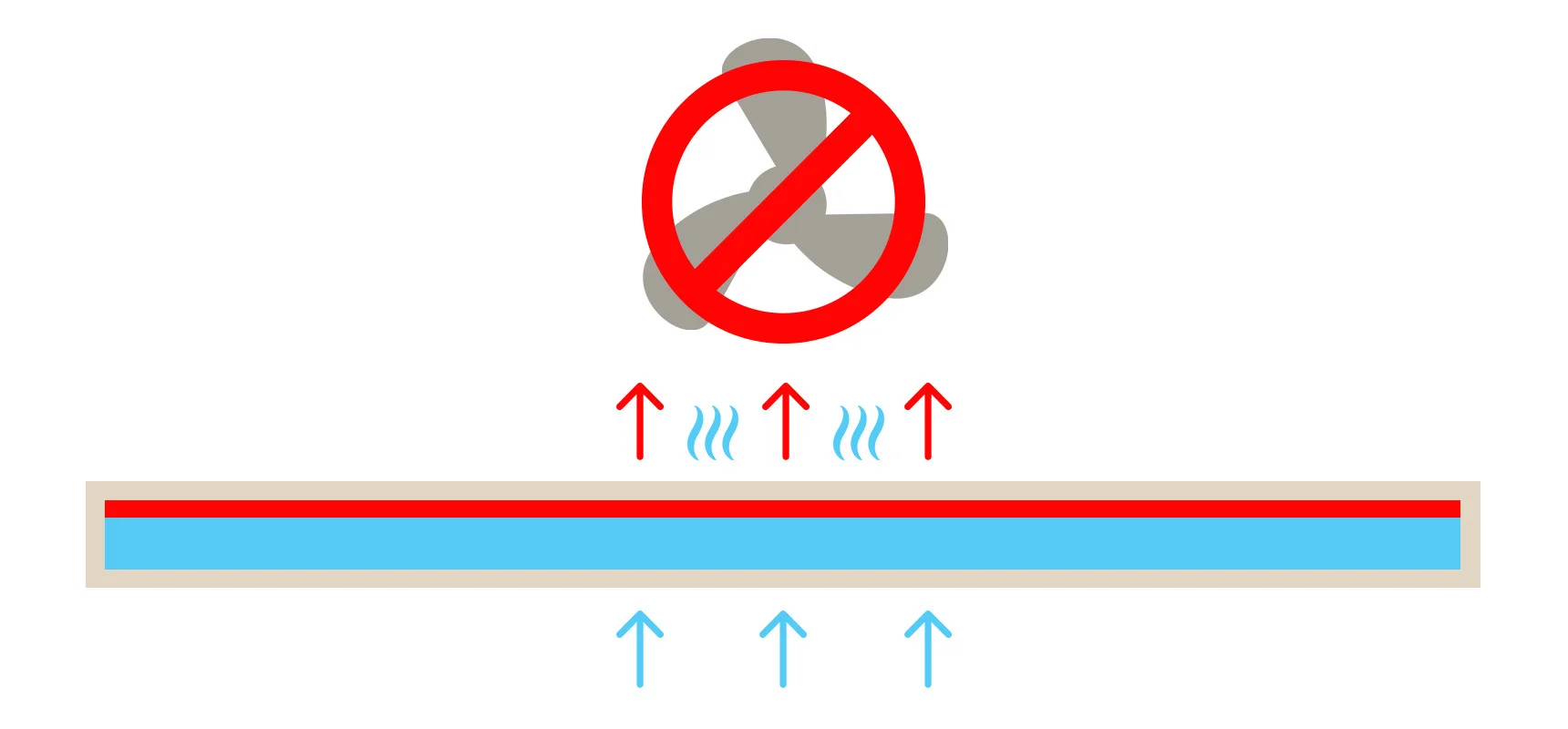

With the Alent Dynamic® method, the wood is heated to a very high temperature in a short time, and the wood is given time to rest.

At first, the temperature driving force counteracts the migration of moisture — as you would expect. But with the fans shut down, the disproportionate heat near the surface of the wood fuels the evaporation of the emerging moisture — effectively cooling the surface down.

Soon, the temperature gradient is reversed and the two forces now act in unison — speeding up the migration even more.

The stress placed on the wood by the heat dissipates, and the surface is remoisturized. Eventually, the moisture and temperature gradients level out, and a new cycle begins.

SAVE TIME AND ENERGY

Save 20 - 60 % electricity

Save 2 - 10 % heat energy

5-20% faster drying time

Save 5-30 % water

Easier to recognize issues within the kiln

INCREASE END-PRODUCT QUALITY

Less risk of deformation due to stress

Less wood discoloration

Fewer process-inflicted cracks

Less resin bleed

Straighter wood

Extract of a News article

The sawmill industry is an electricity-intensive business, where the drying of sawn timber accounts for the greatest need for electricity. The price of electricity is also today more than 2-5 times higher than three years ago, which puts pressure on the sawmill companies financially. At the same time, the quality requirements for delivered timber are increasing with the CLT trend, increased use of beech, oak, and other hard woods. The effects of increased inflation and other events in the world also increase the pressure on sawmills' competitiveness.

The solution is switching to a dynamic drying process and thus 25-60% less electricity costs, 2-10% reduced heating, 5-20% shorter drying time and, not least, significantly higher quality. If you convert the effects into money, it can mean €200,000 per year, as in this typical example for three 230 m3 drying kilns.

Check out these Frequently Asked Questions for more.